Metal Injection Molding (MIM)

MIM process is essentially a technology for producing complex shapes from all types of materials including metals, alloys, and composites. It is cost-effective for small, intricate, and high-volume products.

MIM process:

- Step 1 Preparing feedstock Combine metal powders and binder to produce feedstock. The binder serves as an intermediate processing aid and will be removed after injection molding.

- Step 2 Injection molding MIM parts are formed in the injection molding process similar to the forming of plastic parts.

- Step 3 Binding removal Binder is removed using solvent, thermal furnaces or catalytic process, or a combination of methods.

- Step 4 Sintering The sintering process leads to the elimination of residual binders compacting and the forming of solid metal parts by heat.

Machining

- Turning車削加工

- Milling銑削加工

- Boring鏜孔加工

- Drilling鑽孔加工

- Tapping攻牙加工

- Broaching插溝加工

- Grinding磨床加工

- Honing搪磨加工

- Lapping研磨加工

- Welding焊接加工

- E.D.M放電加工

- Gear Cutting齒輪加工

- Wire Cutting線切割

- Laser Engraving雷射雕刻

- Burnishing精抛加工

- Brazing硬焊加工

Surface Treatment

- Anodize陽極處理

- Chemical Film化學薄膜處理

- Trivalent Chromium Conversion Coating三價鉻處理

- E-Coating電鍍

- EN (Electroless Nickel Plating)無電解鎳

- EP (Electropolishing)電解抛光

- Passivation鈍化

- Heat Treatment熱處理

- Blasting/Tumbling噴砂/研磨

Manufacturing Equipment

STAR CNC Swiss-type Automatic Lathe

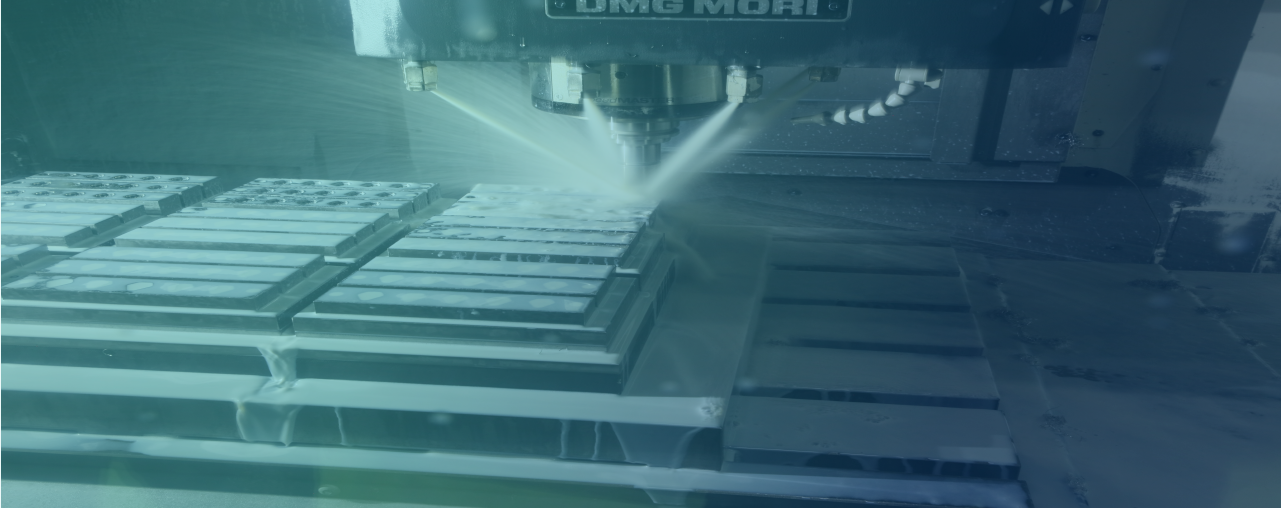

DMG MORI NVX 5080 High Precision Vertical Machining Center

YASDA YMC 430 High Precision Vertical Machining Center

OMAX Waterjet Machine

MICHAEL DECKEL SOE Tool and Cutter Grinder

MICHAEL DECKEL S11 5-axis Manual Universal Tool and Cutter Grinder

DMG 3D Laser Engraving Machine

FANUC All Electric Plastic Injection Moulding Machine

SHIMADZU Vacuum Heat-Treatment Furnaces